Expert Marine Air Conditioning Installation & Maintenance Services

Stay cool and comfortable with high-performance yacht HVAC solutions designed for the harshest marine environments.

Reliable climate control is not a luxury, it is essential for preserving your vessel’s interior, protecting sensitive electronics, and ensuring the comfort of guests and crew. Our specialized yacht services team provides end-to-end marine air conditioning solutions, from custom system design to 24/7 emergency repairs.

Professional Installation: Precision fitting of self-contained units, split systems, and chilled water plants tailored to your yacht’s layout.

Preventative Maintenance: Comprehensive seasonal tune-ups including coil descaling, refrigerant level checks, and electrical diagnostics to prevent mid-season failures.

Emergency Repairs: Rapid troubleshooting for common issues like “HI PS” errors, seawater pump failures, and compressor short circuits.

System Upgrades: Replace aging R-22 units with modern, energy-efficient Inverter Technology for reduced power draw and whisper-quiet operation.

Marine AC systems face unique challenges that domestic units do not. Our technicians are certified to handle:

Corrosion Resistance: Utilizing marine-grade materials like cupronickel or titanium condensers.

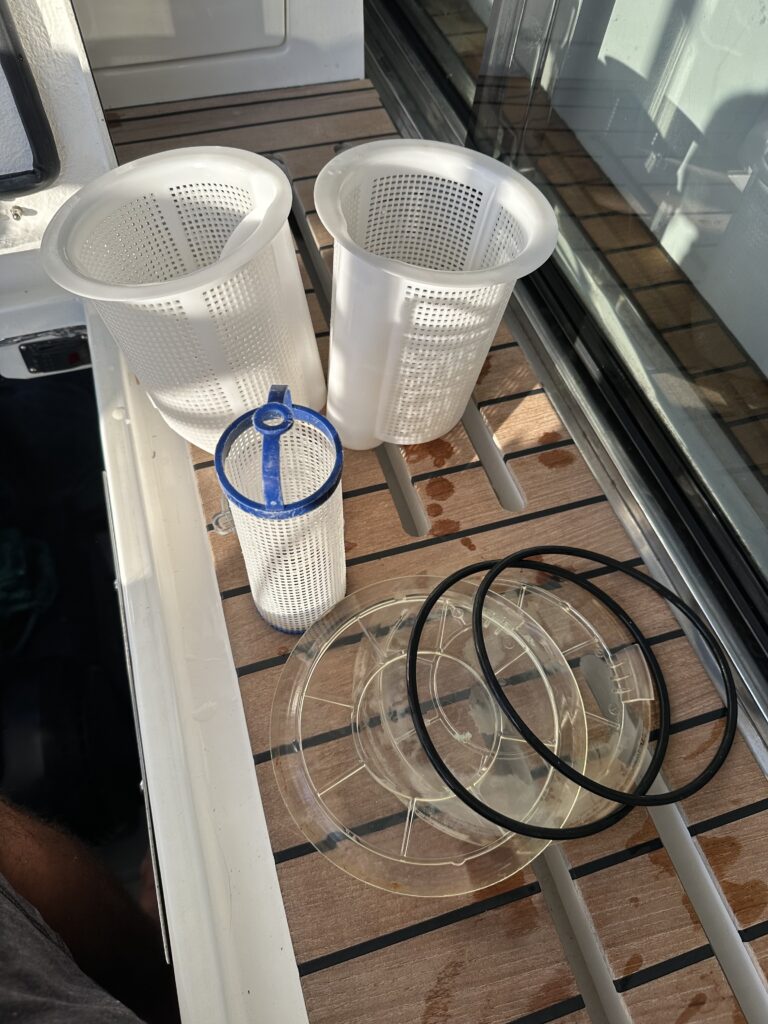

Seawater Circuit Expertise: Maintaining raw water pumps and strainers to ensure optimal heat exchange.

Humidity Control: Advanced dehumidification settings to prevent mold and mildew in cabins.

Weekly: Clean return air filters and check sea strainers.

Monthly: Inspect condensate drains for blockages to avoid interior water damage.

Annually: Professional system flush and refrigerant pressure testing.

Don’t let a faulty AC ruin your next charter or voyage. Whether you need a new installation or a rapid repair, our team is ready to assist.

| Error Code / Fault | Possible Reason | Recommended Action |

|---|---|---|

| HI PS / HPF | High Pressure Fault (Overheating) | Check for obstructed seawater flow. Clean sea strainer or flush condenser coils. |

| LO PS | Low Pressure (Loss of Refrigerant) | Check for refrigerant leaks or extremely low ambient temperatures. Consult a technician. |

| ASF | Air Sensor Failure | Check display cable connections or replace the failed faceplate air sensor. |

| Ice on Coils | Restricted Airflow | Clean or replace return air filters. Check for blocked ducting or closed vents. |

| No Display | Blown Fuse or Power Issue | Check A/C circuit breaker at ship’s panel. Inspect the fuse on the control board. |

| E2 / Low Temp | Evaporator Freezing Protection | Inspect airflow and ensure setpoint is not excessively low. Clean the evaporator coil. |

We provide mobile marine air conditioning services across all major marinas and private docks in the region. We serve all of South Florida.

Be the next one on

Google Reviews

FAQ

ask us

anything

Why is my marine AC discharging little to no water?

A lack of water discharge usually indicates a restriction in the seawater cooling circuit. This is often caused by a clogged sea strainer, marine growth in the through-hull fitting, or an airlock in the pump. If the pump runs dry for too long, it can burn out. We recommend checking your strainer first; if the flow doesn’t return, a professional acid flush may be required to clear the condenser coils.

How often should I descale my marine AC system?

In the warm, nutrient-rich waters of South Florida, we recommend a professional descaling (acid flush) every 6 to 12 months. Over time, barnacles, calcium, and “grass” build up inside the cupronickel heat exchanger, reducing cooling efficiency and causing “HI PS” (High Pressure) errors. Regular flushing extends the life of your compressor and keeps your energy bills lower.

My AC control panel is showing a "HI PS" error. What does it mean?

“HI PS” stands for High Pressure. This is a safety shutdown that occurs when the refrigerant gets too hot because the heat isn’t being transferred to the seawater. The most common causes are a seawater pump failure, a closed seacock, or a blocked strainer. Do not repeatedly reset this error, as it can cause permanent damage to the compressor.

Why does my yacht smell musty when the air conditioning is on?

Musty odors are usually caused by biological growth (mold or mildew) in the evaporator coils or standing water in the condensate drain pan. If your boat’s pitch or roll prevents the pan from draining completely, the stagnant water becomes a breeding ground for bacteria. We provide specialized evaporator cleaning and can treat your drain pans with antimicrobial tablets to keep your cabin air fresh.

Is it worth upgrading my old AC to a "Variable Speed" Inverter system?

Yes. Modern Inverter-based systems (like the Dometic Variable Speed series) are up to 30-40% more efficient than traditional units. They eliminate the massive “startup surge” that trips shore power breakers and run at whisper-quiet speeds once the cabin reaches the set temperature. They also provide much better dehumidification, which is critical for preserving your yacht’s woodwork and upholstery.

We'd Love To Hear From You